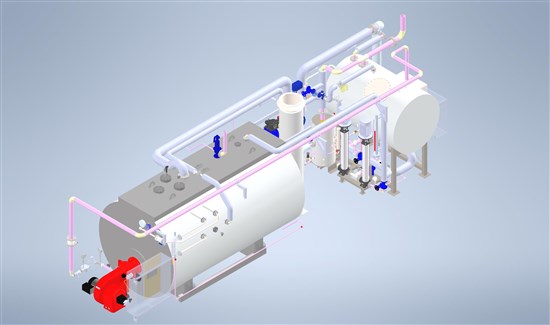

STEAM BOILERS

Under the combined effect of the rise in temperature and their concentration in the boiler, dissolved salts precipitate in the form of scale on the surface of the walls. The make-up water for steam cycles therefore systematically undergoes demineralisation, which is more or less complete depending on the boiler operating pressure. Dissolved gases, oxygen and carbon dioxide, which are the main causes of corrosion, are advantageously eliminated by thermal degassing. Chemical conditioning of the circuit will complete these treatments in order to :

- eliminate residual oxygen

- sequestering and dispersing mineral sludge

- passivate heat exchange walls to control corrosion

- neutralise the carbonic acidity of condensate returns

TRESCH Traitement des Eaux

implements complete steam boiler water treatment solutions

- Technical and administrative support

- Balance of steam production and associated water consumption

- Presence at regulatory openings

- Optimising operation: softeners, osmosis units, etc.

- Optimising purges: saving water, products and fuel

- Supply of the most suitable equipment

- Filtration, softening, demineralisation, reverse osmosis, dosing units...

- Calculation of return on investment (ROI), equipment eligible for Energy Savings Certificates

- Supply of packaging products

- A range of products with specific actions for boiler water treatment and steam treatment: MAJOVAP, CARBOVAP, ET64...

- A range of single products for all-round treatment: MAJO62S, MAJO61S, MAJO94...

- A complete solution

- Supply of the equipment and analysis products needed by the customer to monitor his treatment

- Setting up a monitoring and maintenance plan

- Setting up a logbook to monitor the boiler room

- Chemical assistance contract carried out by our teams